Overview

DB Electrical Alternators

DB Electrical keeps watercrafts moving forward with quality aftermarket alternators. We work directly with factories to ensure each component is manufactured to our exacting quality control standards. But because there is no middleman, we can offer these exceptional-quality electrical components at low factory direct prices.

With DB Electrical alternators, you’ll get …

- Superior Quality Every Time – Our aftermarket alternators deliver performance that’s equivalent to the original.

- Direct-Fit OEM Replacement Parts – DB Electrical aftermarket alternators are designed for perfect fitment to replace the ones that originally came with your vehicle.

- Engineer-Tested Excellence – Our alternators go through a rigorous testing program to ensure optimal performance. Most alternators are supplied with their final test results and performance curve.

Reasons to choose DB Electrical for your next alternator:

- Built to Take the Heat – Most DB Electrical alternators offer high-temperature epoxy, heavy-duty rectifiers, high-quality regulators, top-quality bearings and high-temperature grease for better charging and longer life under high-heat environments.

- Corrosion Resistance – Plated fans, pulleys and hardware offer protection against rust-producing dampness.

- Flame Arrestor Screens – Where applicable, alternators come with these screens to meet Marine SAEJ1171 Certification as laid out by the SAE.

- Brand New Alternator – Never settle for a secondhand one. Many places will try to sell you a used alternator for about the price we’ll sell you a new one.

The DB Electrical Advantage – 1-Year Warranty

DB Electrical delivers exceptional value for products that we stand behind with our total-confidence 1-year warranty. Yes, you have a full year to make sure your alternator meets your expectations.

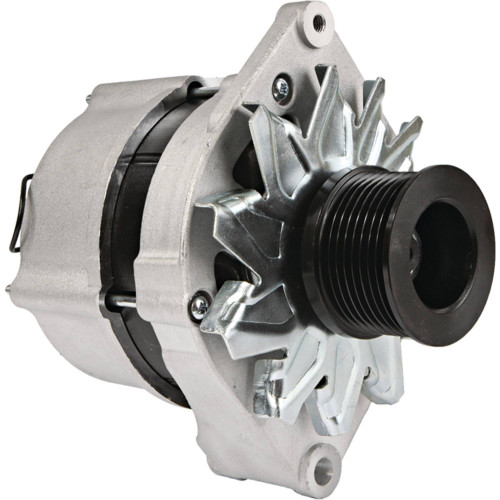

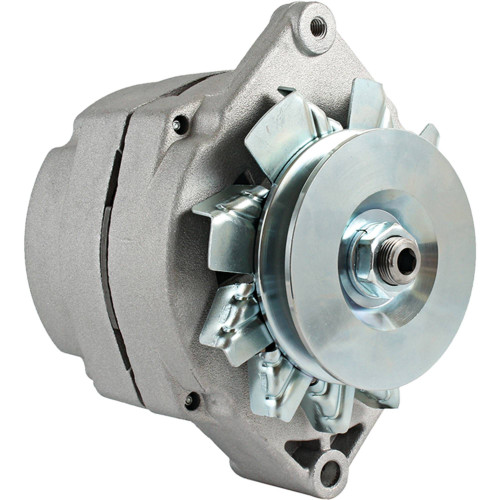

Item Number: 400-24175

100% Brand New Aftermarket Part From DB Electrical

Product Specs

| Item Condition | Aftermarket Part |

| Unit Type | Alternator |

| Part Type | UNIT |

| Voltage | 12 |

| Rotation | CW |

| Amperage | 120 |

| Regulator | IR |

| Fan Type | EF |

| Fits | NEW HOLLAND 8-GROOVE PULLEY |

OEM Chaff Screen May Not Fit on the Replacement Type Units |

Applications List

Select Make & Type

| MAKE | TYPE | MODEL | YEAR | ENGINE |

| JOHN DEERE | Combine | 1170 | All | All |

| JOHN DEERE | Combine | 1450 | All | 6.8L Engine |

| JOHN DEERE | Combine | 1450 CWS | All | All |

| JOHN DEERE | Combine | 1550 | All | 8.1L Engine |

| JOHN DEERE | Combine | 1550 CWS | All | All |

| JOHN DEERE | Cotton Picker | 7455 | All | All |

| JOHN DEERE | Cotton Picker | 9935 | All | All |

| JOHN DEERE | Cotton Picker | 9970 | All | 6076 Diesel |

| JOHN DEERE | Cotton Picker | 9970 | All | 6081 Diesel |

| JOHN DEERE | Cotton Picker | 9976 | All | 6081 Diesel |

| JOHN DEERE | Cotton Picker | 9986 | All | 6081 Diesel |

| JOHN DEERE | Engine | 4039 | All | All |

| JOHN DEERE | Engine | 4045 | All | All |

| JOHN DEERE | Engine | 6059 | All | All |

| JOHN DEERE | Engine | 6068 | All | All |

| JOHN DEERE | Engine | 6101 | All | All |

| JOHN DEERE | Engine – Marine | 4039DFM (Code 3113) | All | 3.9L – 239ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4039DFM (Code 3116) | All | 3.9L – 239ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045DFM50 (Code 3108) | All | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045DFM70 (Code 3108) | 2004 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045DFM70 (Code 3108) | 2005 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045DFM70 (Code 3108) | 2006 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045DFM70 (Code 3108) | 2007 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM (Code 3113) | All | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM (Code 3116) | All | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM50 (Code 3108) | All | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM75 (Code 3141) | 2004 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM75 (Code 3141) | 2005 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM75 (Code 3141) | 2006 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 4045TFM75 (Code 3141) | 2007 | 4.5L – 276ci – 4cyl |

| JOHN DEERE | Engine – Marine | 6068DFM (Code 3113) | All | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068DFM (Code 3116) | All | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068SFM50 (Code 3141) | 2004 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068SFM50 (Code 3141) | 2005 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068SFM50 (Code 3141) | 2006 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068SFM50 (Code 3141) | 2007 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM (Code 3113) | All | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM (Code 3116) | All | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM50 (Code 3108) | All | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM75 (Code 3141) | 2004 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM75 (Code 3141) | 2005 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM75 (Code 3141) | 2006 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM75 (Code 3141) | 2007 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM76 (Code 3141) | 2004 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM76 (Code 3141) | 2005 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM76 (Code 3141) | 2006 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6068TFM76 (Code 3141) | 2007 | 6.8L – 414ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6076AFM (Code 3134) | All | 7.6L – 466ci – 6cyl |

| JOHN DEERE | Engine – Marine | 6076AFM30 (Code 3134) | All | 7.6L – 466ci – 6cyl |

| JOHN DEERE | Loader | 530B Log Loader | All | All |

| JOHN DEERE | Loader | 535 Log Loader | All | All |

| JOHN DEERE | Skidder | 360D | All | All |

| JOHN DEERE | Skidder | 460D | All | All |

| JOHN DEERE | Skidder | 540G-III | All | All |

| JOHN DEERE | Skidder | 548G-III | All | All |

| JOHN DEERE | Skidder | 560D | All | All |

| JOHN DEERE | Skidder | 640G-III | All | All |

| JOHN DEERE | Skidder | 648G-III | All | All |

| JOHN DEERE | Skidder | 748G-III | All | All |

| JOHN DEERE | Sprayer | 6700 | All | All |

| JOHN DEERE | Windrower | 4890 | All | All |

| JOHN DEERE | Windrower | 4895 | All | All |

| JOHN DEERE | Windrower | 4990 | All | All |

| JOHN DEERE | Windrower | 4995 | All | All |

| NEW HOLLAND | Windrower | HW300 | 1998 | |

| NEW HOLLAND | Windrower | HW300 | 1999 | |

| NEW HOLLAND | Windrower | HW300 | 2000 | |

| NEW HOLLAND | Windrower | HW300 | 2001 | |

| NEW HOLLAND | Windrower | HW300 | 2002 | |

| NEW HOLLAND | Windrower | HW300 | 2003 | |

| NEW HOLLAND | Windrower | HW300 | 2004 | |

| NEW HOLLAND | Windrower | HW320 | 1998 | |

| NEW HOLLAND | Windrower | HW320 | 1999 | |

| NEW HOLLAND | Windrower | HW320 | 2000 | |

| NEW HOLLAND | Windrower | HW320 | 2001 | |

| NEW HOLLAND | Windrower | HW320 | 2002 | |

| NEW HOLLAND | Windrower | HW320 | 2003 | |

| NEW HOLLAND | Windrower | HW320 | 2004 |

Replaces These Part Numbers

| ARROWHEAD | ABO0264, 400-24175, B0120484027, BAL9972N |

| BOSCH | 9-120-060-042, F-005-A00-025 |

| CARGO | 113531 |

| J&N Electrical Products | 400-24032 |

| JOHN DEERE | AE52707, AT185951, SE501343, TY24486 |

| LESTER | 12372, 12373 |

| NEW HOLLAND | 86537977, 86577814, 87020406 |

| NSA | ALT-2231 |

| UNIPOINT | ALT-2231 |

| WAI | 1-2500-31BO |

Frequently Asked Questions

|

Q: Do I need a larger charge wire for a High Output unit? |

Reviews

There are no reviews yet.