Overview

DB Electrical Alternators

DB Electrical keeps vehicles of every shape and size moving forward – from mowers, motorcycles and ATVs to automobiles, tractors, pickups and large commercial trucks. We work directly with factories to ensure each component is manufactured to our exacting quality control standards. But because there is no middleman, we can offer these exceptional-quality electrical components at low factory direct prices.

With DB Electrical alternators, you’ll get …

- Superior Quality Every Time – Our aftermarket alternators deliver performance that’s equivalent to the original.

- Direct-Fit OEM Replacement Parts – DB Electrical aftermarket alternators are designed for perfect fitment to replace the ones that originally came with your vehicle.

- Engineer-Tested Excellence – Our alternators go through a rigorous testing program to ensure optimal performance. Most alternators are supplied with their final test results and performance curve.

Reasons to choose DB Electrical for your next alternator:

- Built to Take the Heat – Most DB Electrical alternators offer high-temperature epoxy, heavy-duty rectifiers, high-quality regulators, top-quality bearings and high-temperature grease for better charging and longer life under high-heat environments.

- Depth of Inventory – Find both common and hard-to-find alternators for virtually any type of vehicle to travel over road, trail or water.

- Brand New Alternator – Never settle for a secondhand one. Many places will try to sell you a used alternator for about the price we’ll sell you a new one.

The DB Electrical Advantage – 1-Year Warranty

DB Electrical delivers exceptional value for products that we stand behind with our total-confidence 1-year warranty. Yes, you have a full year to make sure your alternator meets your expectations.

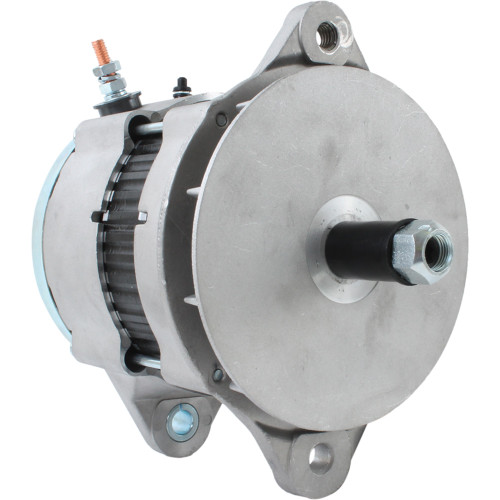

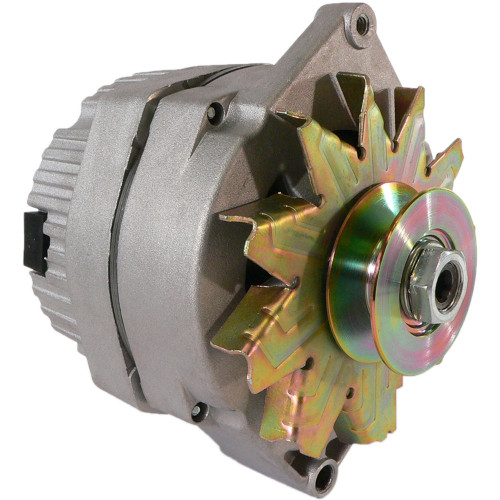

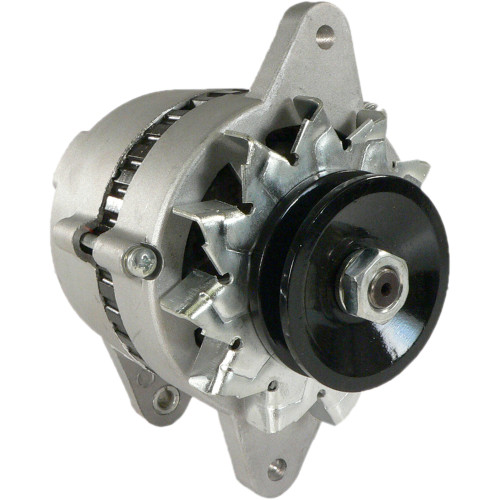

Item Number: 400-52197

100% Brand New Aftermarket Part From DB Electrical

Product Specs

| Item Condition | Aftermarket Part |

| Unit Type | Alternator |

| Part Type | UNIT |

| Voltage | 24 |

| Rotation | CW |

| Amperage | 80 |

| Regulator | IR |

| Fan Type | EF |

| Fits | CATERPILLAR / DAIHATSU |

Applications List

Select Make & Type

| MAKE | TYPE | MODEL | YEAR | ENGINE |

| CATERPILLAR | Asphalt Paver | AP755 | Cat. C7 | |

| CATERPILLAR | Cold Planer | PM-200 | Cat. C18 | |

| CATERPILLAR | Cold Planer | PM-201 | Cat. C18 | |

| CATERPILLAR | Cold Planer | PM-465 | Cat. 3406 | |

| CATERPILLAR | Compactor | 815F Series II Soil | 2006 – On | Cat. C9 |

| CATERPILLAR | Compactor | 816F Series II Landfill | 2007 | Cat. C9 |

| CATERPILLAR | Compactor | 816F Series II Landfill | 2008 | Cat. C9 |

| CATERPILLAR | Compactor | 816F Series II Landfill | 2009 | Cat. C9 |

| CATERPILLAR | Compactor | 825H Soil | 2005 – On | Cat. C15 |

| CATERPILLAR | Compactor | 826H Landfill | 2004 – On | Cat. C15 |

| CATERPILLAR | Compactor | 836H Landfill | 2004 – On | Cat. C18 |

| CATERPILLAR | Excavator | 320C | 1999 | Cat. 3066 |

| CATERPILLAR | Excavator | 320C | 2000 | Cat. 3066 |

| CATERPILLAR | Excavator | 320C | 2001 | Cat. 3066 |

| CATERPILLAR | Excavator | 320C | 2002 | Cat. 3066 |

| CATERPILLAR | Excavator | 320C | 2003 | Cat. 3066 |

| CATERPILLAR | Excavator | 320C | 2004 | Cat. 3066 |

| CATERPILLAR | Excavator | 320C | 2005 | Cat. 3066 |

| CATERPILLAR | Excavator | 320D FM | 2005 – On | Cat. C6.4 |

| CATERPILLAR | Excavator | 320D Log Loader | 2005 – On | Cat. C6.4 |

| CATERPILLAR | Excavator | 322C FM LGP | 2001 – On | Cat. 3126B |

| CATERPILLAR | Excavator | 322C Forest Swing | 2001 – On | Cat. 3126B |

| CATERPILLAR | Excavator | 324D FM LGP | 2006 – On | Cat. C7 |

| CATERPILLAR | Excavator | 325C Forest Swing Machine | 2001 – On | Cat. 3126B |

| CATERPILLAR | Excavator | 325D Forest Swing Machine | 2006 – On | Cat. C7 |

| CATERPILLAR | Excavator | 325D Material Handler | 2006 – On | Cat. C7 |

| CATERPILLAR | Excavator | 330C | 2002 – On | Cat. C9 |

| CATERPILLAR | Excavator | 330C Forest Swing Machine | 2002 – On | Cat. C9 |

| CATERPILLAR | Excavator | 330C L | 2002 – On | Cat. C9 |

| CATERPILLAR | Excavator | 330C LN | 2002 – On | Cat. C9 |

| CATERPILLAR | Excavator | 330D Custom Waste Handler | 2006 – On | Cat. C9 |

| CATERPILLAR | Excavator | 330D Forest Swing Machine | 2006 – On | Cat. C9 |

| CATERPILLAR | Excavator | 330D Material Handler | 2006 – On | Cat. C9 |

| CATERPILLAR | Excavator | 365B | 1998 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B | 1999 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B | 2000 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B | 2001 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L | 1998 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L | 1999 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L | 2000 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L | 2001 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L Material Handler | 1998 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L Material Handler | 1999 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L Material Handler | 2000 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L Material Handler | 2001 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L U Front Shovel | 1998 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L U Front Shovel | 1999 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L U Front Shovel | 2000 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B L U Front Shovel | 2001 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B Material Handler | 1998 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B Material Handler | 1999 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B Material Handler | 2000 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B Material Handler | 2001 | Cat. 3196 |

| CATERPILLAR | Excavator | 365B Series II | 2001 – On | Cat. 3196 |

| CATERPILLAR | Excavator | 365C L | 2004 – On | Cat. C15 |

| CATERPILLAR | Excavator | 365C L Material Handler | 2004 – On | Cat. C15 |

| CATERPILLAR | Excavator | 374D L | 2008 – On | Cat. C15 |

| CATERPILLAR | Excavator | 385C | 2003 – On | Cat. C18 |

| CATERPILLAR | Excavator | 385C FS | 2003 – On | Cat. C18 |

| CATERPILLAR | Excavator | 385C L | 2003 – On | Cat. C18 |

| CATERPILLAR | Excavator | 385C Material Handler | 2003 – On | Cat. C18 |

| CATERPILLAR | Front Shovel | 385C | 2005 | Cat. C18 |

| CATERPILLAR | Front Shovel | 385C | 2006 | Cat. C18 |

| CATERPILLAR | Front Shovel | 385C | 2007 | Cat. C18 |

| CATERPILLAR | Front Shovel | 385C | 2008 | Cat. C18 |

| CATERPILLAR | Front Shovel | 385C | 2009 | Cat. C18 |

| CATERPILLAR | Front Shovel | 385C | 2010 | Cat. C18 |

| CATERPILLAR | Front Shovel | 5090B | 2002 | Cat. 3456 |

| CATERPILLAR | Front Shovel | 5090B | 2003 | Cat. 3456 |

| CATERPILLAR | Front Shovel | 5090B | 2004 | Cat. 3456 |

| CATERPILLAR | Front Shovel | 5090B | 2005 | Cat. 3456 |

| CATERPILLAR | Wheel Loader | 928G | 1996 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 1997 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 1998 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 1999 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 2000 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 2001 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 2002 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928G | 2003 | Cat. 3056 |

| CATERPILLAR | Wheel Loader | 928H | 2008 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928H | 2009 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928H | 2010 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928H | 2011 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928HZ | 2007 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928HZ | 2008 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928HZ | 2009 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928HZ | 2010 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928HZ | 2011 | Cat. C6.6 |

| CATERPILLAR | Wheel Loader | 928HZ | 2012 | Cat. C6.6 |

Replaces These Part Numbers

| ARROWHEAD | AND0554, ND021080-0730, ND101211-8272, ND211-8004, ND101211-8341 |

| CATERPILLAR | 0R4841, 10R-9789, 10R-9790, 177-9953, 197-8820, 257-9466 |

| DENSO | 101211-8270, 101211-8271, 101211-8272, 101211-8340, 101211-8341 |

| DIXIE CHOPPER | 146-50204 |

| J&N Electrical Products | 400-52144, 400-52197 |

| LESTER | 12669, 12670 |

Frequently Asked Questions

|

Q: Do I need a larger charge wire for a High Output unit? |

Reviews

There are no reviews yet.